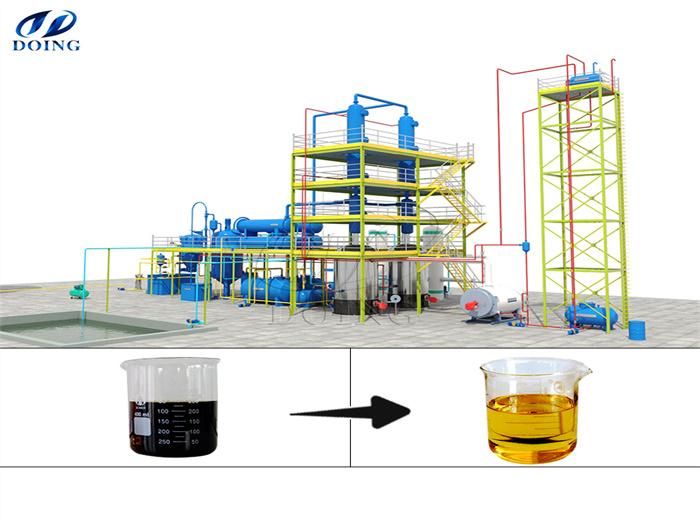

Used motor oil itself is a renewable resource, which can be recycled and distilled into diesel fuel. DOING Company's used oil distillation plant has the mature technology to help you distill used motor oil for diesel fuel and create great profits for you.

Waste oil refining to diesel plant

Here, I will introduce the waste oil to diesel fuel distillation process of used oil distillation plant to let you know more details.

1. First, pump the collected used motor oil into the distillation reactor.

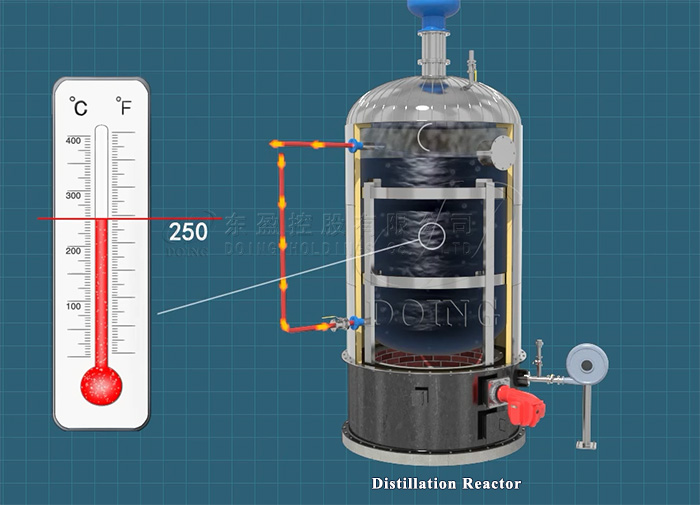

Through the heating oil heating system and the fuel heating system, the used motor oil is boiled and gasified, the impurities in the waste oil will continue to settle during the heating process, and the oil gas will enter the condensation system after being catalyzed by the catalyst.

2. Let the oil gas pass through the catalytic tower. The reactants in the catalytic tower can remove the colloid and wax in the oil gas generated by the used motor oil, and the oil will become clearer after degumming and dewaxing.

The distillation reactor heating tepmerature

3. The oil gas enters the condensing system after the catalytic reaction, and the oil gas is liquefied into diesel fuel through the circulating cooling water in the condensing system and enters the temporary storage tank.

4. The diesel fuel refined by the used oil distillation plant is introduced into the decolorization system, and the color of the diesel after decolorization is clearer and brighter.

5. The non-condensable part of the gas first passes through the water sealing system, and then returns to the reactor for full combustion.

6. For the smoke and dust emitted by fuel combustion, DOING used oil distillation plant has specially designed a desulfurization and dust removal purification system to treat them, which can meet the emission standards of different countries.

Desulfurization and dust removal purification system

The diesel oil yield of DOING used oil distillation plant is generally around 80%-85%. The residual material in the furnace after distillation is bituminous and can be directly used for paving or sold to an asphalt plant for further refining. Diesel fuel refined from used motor oil can be directly added to tractors, trucks, ships, generators, etc.

The above is the process of distilling diesel fuel from used motor oil. It does not sound complicated, but it requires qualified, stable, safe and environmentally friendly used oil distillation plants to carry out it. So it is particularly important to choose a professional and reliable used oil distillation plant manufacturer.

If you want to do the used motor oil or other waste oil/pyrolysis oil to diesel fuel distillation projects, it is recommended to select the used oil distillation plant produced by Henan Doing Company. With 11+ years of work experience, responsible business team and engineer team, DOING will escort your project to the ground!